The processing of crude oil is a complex industry that requires meticulous attention to detail at each stage. Filtration and separation are crucial steps in ensuring quality and purity. Wire mesh is a key component of this process, as it removes contaminants and impurities.

Understanding Wire Mesh

The wire mesh is an extremely versatile material made up of metal wires interlocked in a grid. Metals like stainless steel, nickel or galvanized steel can be used to create wire mesh. Each metal has specific properties that are suited for different industrial applications. A customization option is possible based on the filtration requirements.

Understanding Crude Oil Separation and Filtration

It’s important to understand the basics of crude oil separation and filtration before exploring the role of wire mesh. Crude oil is contaminated with water, solid particles and other contaminants. Filtration captures these impurities using different media, whereas separation isolates components such as oil, gas and water.

The Role of Wire Mesh in Filtration

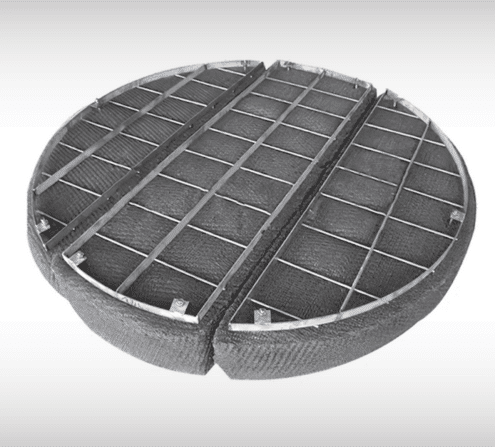

The effectiveness of wire mesh as a filter media is the primary reason why it plays such a crucial role in crude oil purification. The intricate patterns of woven wire mesh provide a porous yet durable structure that traps solid contaminants and particles. This type of mesh can be used in the primary filtration stage to remove larger debris and particles from crude oil.

Filtration processes also use welded wire mesh in addition to woven mesh. Welded mesh is known for its sturdy construction and ability to withstand high temperatures and pressures. It is, therefore, suitable for secondary filtering stages, where finer filtration may be required to achieve the desired purity level in crude oil.

The Role of Wire Mesh in Separation

Wire mesh is used for a variety of purposes in crude oil separation. The purpose depends on the specific process. The wire mesh made of stainless steel is used in many demisting applications because it’s corrosion-resistant and durable. Wire mesh demister separates liquid droplets and gas streams to ensure that the extracted gases are clean before further processing.

Photo Courtesy: Yogesh Kundu

Benefits of using wire mesh in crude oil processing

Wire mesh integration into crude oil processing has several advantages. Wire mesh improves the efficiency of the process by facilitating effective separation and filtration, thus reducing downtime. Second, the durability and reliability of materials such as steel metal mesh contributes to overall sustainability.

Wire mesh also contributes to sustainability in the environment by minimizing waste and optimizing resources. In order to meet environmental regulations, it is important that industries produce crude oil with a higher purity and cleaner output.

Innovations & Future Trends

In the future, further advancements in wire-mesh technology will revolutionize crude oil extraction. Wire mesh is being improved by innovations such as coatings and advanced alloys. The integration of automation and smart technologies will streamline processes and offer real-time monitoring capabilities and predictive maintenance.

Conclusion

Wire mesh is now an essential component of crude oil separation and filtration processes. Its versatility and durability make it the preferred choice of various industries that strive to improve product quality and operational efficiency. Wire mesh will continue to be a key component of the future of crude oil processing as technologies and industries evolve.

Contact a wire mesh company like SRK Metals for more information about how wire mesh can be beneficial to your industrial applications. Discover their wide range of high-quality wire mesh products that are designed to meet demanding industrial requirements. Their wire mesh products are suitable for different industries and fields, including oil & gas, filtration, fencing, automotive, construction, agriculture, interior design, fireplace screening, cages, food and beverage, grill, transport, insect mesh, security, etc.

Published By: Aize Perez