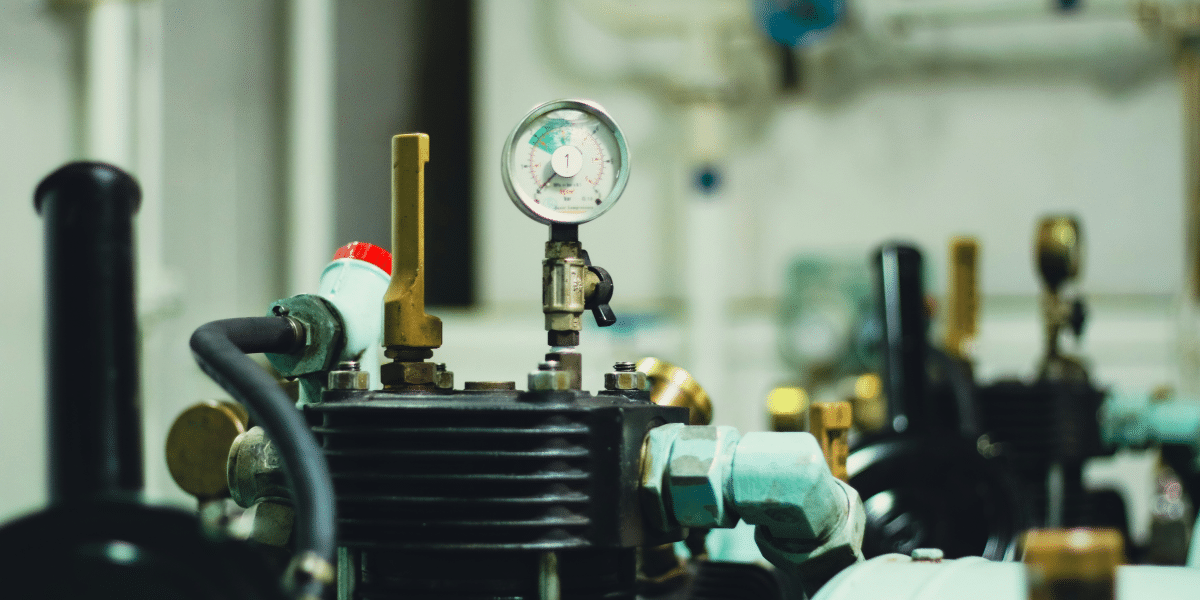

In a world where efficiency and power reign supreme, the unsung hero known as the air compressor quietly plays a pivotal role in various industries. From manufacturing plants to construction sites, these mechanical marvels serve as the lifeblood of countless operations. But did you know that not all air compressors are created equal? Join us on an enlightening journey as we delve into the diverse types of air compressors, unraveling their unique features and applications.

Reciprocating Compressors: Powerhouses in Motion

Imagine a symphony of mechanical motion, where pistons dance to the rhythm of compressed air. This is the world of reciprocating compressors, where raw power meets precision engineering. Operating on the principle of positive displacement, these workhorses compress air by reducing its volume through reciprocating motion.

With their robust design and ability to generate high pressures, reciprocating compressors are well-suited for heavy-duty applications. From powering pneumatic tools in automotive workshops to supplying compressed air for industrial processes, these stalwart machines prove their mettle time and again. However, their reliance on moving parts necessitates regular maintenance to ensure optimal performance and longevity.

Air Powered Services are the compressed air specialists in Australia, offering a comprehensive range of reciprocating compressors tailored to meet the unique needs of businesses across various sectors. Whether it’s a small-scale operation or a large industrial facility, their expertise ensures seamless integration and reliable performance.

Rotary Screw Compressors: Silent Titans of Efficiency

In the realm of air compressors, rotary screw compressors stand out as silent titans, effortlessly blending power with efficiency. Unlike their reciprocating counterparts, these machines operate on a continuous flow principle, where twin screws intermesh to compress air within a sealed chamber.

What sets rotary screw compressors apart is their whisper-quiet operation and exceptional reliability. With fewer moving parts and minimal vibration, these workhorses deliver consistent performance with minimal maintenance requirements. This makes them the preferred choice for applications where uninterrupted operation is paramount, such as medical facilities, laboratories, and pharmaceutical production.

For businesses seeking a seamless blend of efficiency and performance, Air Powered Services offers a range of rotary screw compressors designed to meet the demands of modern industries. With their cutting-edge technology and unwavering commitment to quality, these compressors deliver unparalleled reliability and energy savings, ensuring maximum productivity with minimal downtime.

Centrifugal Compressors: Masters of Airflow Dynamics

Enter the realm of centrifugal compressors, where the laws of physics converge to harness the power of kinetic energy. Unlike their counterparts, which rely on positive displacement, centrifugal compressors leverage centrifugal force to accelerate and compress air within a spinning impeller.

Renowned for their high flow rates and energy efficiency, centrifugal compressors excel in applications where large volumes of compressed air are required. From air separation plants to petrochemical refineries, these masters of airflow dynamics play a pivotal role in sustaining critical operations. However, their complex design and precise engineering demand skilled maintenance to ensure optimal performance and longevity.

For businesses seeking to harness the power of centrifugal compression, Air Powered Services offers a range of solutions tailored to meet the demanding requirements. With their expertise and dedication to excellence, they empower businesses to unleash the full potential of compressed air technology, driving innovation and progress across diverse industries.

The world of air compressors is a vast and multifaceted landscape, with each type offering unique advantages and applications. Whether it’s the raw power of reciprocating compressors, the silent efficiency of rotary screw compressors, or the dynamic airflow of centrifugal compressors, these machines continue to redefine the boundaries of possibility. So the next time you marvel at the wonders of modern industry, remember the unsung hero quietly humming in the background—the air compressor.

Published by: Nelly Chavez